Nonwovens Production

NOWOtex – Nonwovens Production at State-of-the-Art Production Plants

As a nonwovens specialist, NOWOtex uses state-of-the-art machinery and process technologies. The selection of the fibre blend at the start of the production process for nonwovens already has a major influence on the properties of the end product. NOWOtex can process man-made, natural and recycled fibres depending on the customers’ requirements.

Web forming

The procedure chain from raw material preparation to carding process serves to open the fibre flocks all the way to individual fibres, and to ensure parallelised and homogenous distribution. The resulting fibrous web is then fed into the corresponding bonding technology in multiple layers.

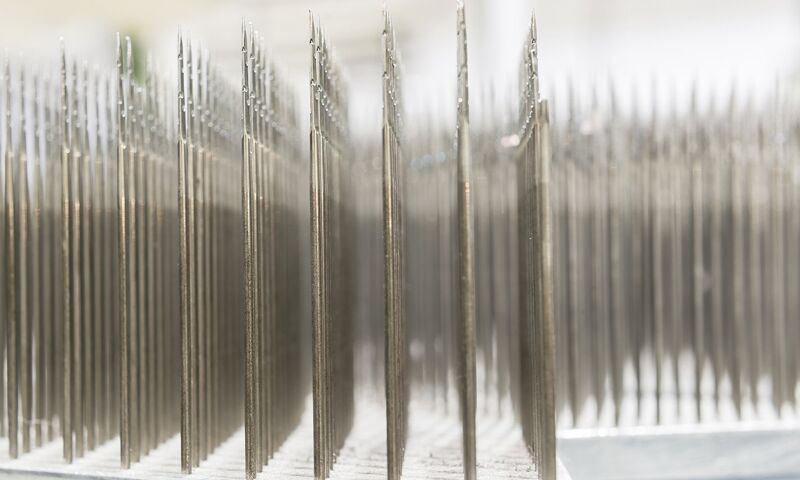

Bonding

NOWOtex uses various different processes for the bonding of nonwovens. Whether mechanical or thermal bonding is used, the production of nonwovens is always precise to ensure that it meets your product requirements. In the case of mechanically bonded nonwovens, the individual fibres are realigned and connected to each other using notched needles. Thermal bonding uses the thermoplastic behaviour of special man-made fibres. They provide the overall compound with strength by functioning as binding points between the fibres.

The staff at NOWOtex are always at your disposal should you have any questions concerning the desired production process.